In the world of packaging design, understanding the concept of a dieline is crucial for creating effective, visually appealing, and functional packaging. A dieline serves as the blueprint for a package, guiding the manufacturing process and ensuring that the final product meets both aesthetic and structural requirements. This article will delve into what is a dieline in packaging, its importance, components, and the best practices for creating an effective dieline.

Understanding Dielines

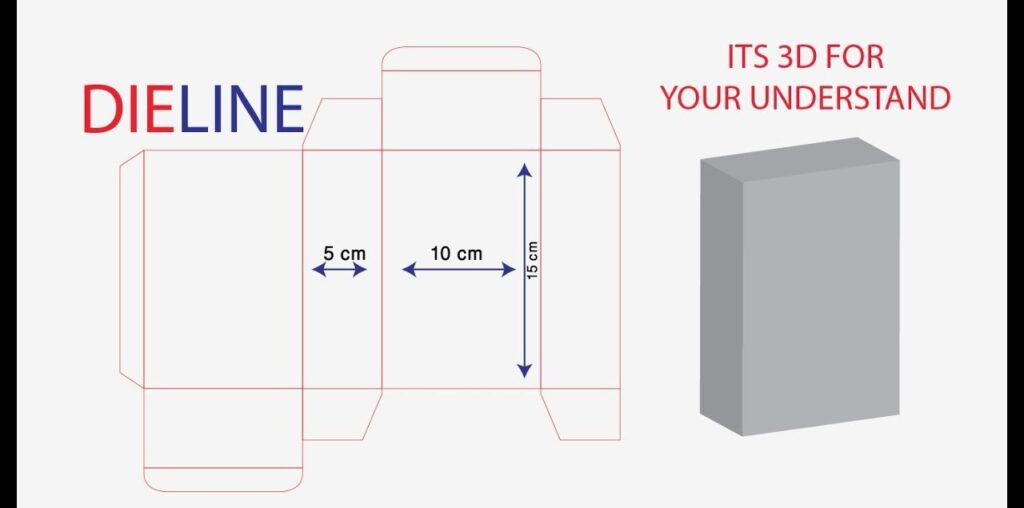

A dieline is a flat representation of a three-dimensional package, illustrating how it will be cut, folded, and assembled. It is typically created using graphic design software and outlines all aspects of the packaging, including cuts, folds, perforations, and bleed areas. The dieline is essential for both the designer and the printer, serving as a communication tool that ensures everyone involved in the packaging process understands the design’s specifications.

Key Components of a Dieline

- Cut Lines: These lines indicate where the material will be cut to create the final shape of the package. They are usually marked with solid lines.

- Fold Lines: Represented by dashed or dotted lines, fold lines indicate where the packaging will be folded to form the final structure.

- Perforation Lines: These lines show where the material will be perforated to allow easy tearing or opening of the package. They are typically indicated by a series of small dots.

- Bleed Area: This area extends beyond the cut line and is crucial for designs that go all the way to the edge of the packaging. The bleed ensures that no unprinted edges are visible in the final product.

- Registration Marks: These marks are used to ensure that colors align correctly during the printing process, particularly important for designs that use multiple colors or images.

- Dimensions: Accurate measurements of the packaging size are included to ensure that the dieline corresponds with the desired final product dimensions.

Importance of Dielines in Packaging

Creating an effective dieline is paramount for several reasons:

1. Ensures Accuracy

A well-constructed dieline ensures that the final product accurately reflects the designer’s vision. It helps prevent costly mistakes during production, such as misaligned graphics or incorrect dimensions.

2. Facilitates Production

Dielines streamline the production process by providing clear instructions for cutting and assembling the packaging. This efficiency reduces production time and minimizes waste, contributing to cost savings.

3. Enhances Visual Appeal

A dieline allows designers to visualize how graphics will look on the final product. This helps in ensuring that the design elements align properly, creating an aesthetically pleasing package that attracts consumers.

4. Improves Functionality

Beyond aesthetics, a well-designed dieline ensures that the packaging functions correctly. For example, it can dictate how well a box opens, how products are displayed, and how easy it is for consumers to access the contents.

Best Practices for Creating Dielines

Creating an effective dieline requires careful planning and attention to detail. Here are some best practices to consider:

1. Use Design Software

Utilizing professional design software like Adobe Illustrator or CAD programs can significantly enhance the accuracy of your dieline. These tools allow for precise measurements and easy manipulation of design elements.

2. Incorporate Clear Labels

Labeling different components of the dieline clearly can help everyone involved in the production process understand the design. Use annotations for cut lines, fold lines, and any special instructions.

3. Consider the Material

Different materials may require specific considerations when creating a dieline. For example, a thicker cardstock may necessitate wider fold lines compared to a thinner paper. Understanding the characteristics of the material will help ensure that the final product functions as intended.

4. Test with Prototypes

Before finalizing the dieline, create prototypes of the packaging to test its functionality and aesthetics. This process can help identify potential issues and make necessary adjustments before mass production.

5. Stay Updated on Trends

Packaging design trends are constantly evolving. Keeping abreast of the latest trends can inspire innovative dieline designs that stand out on store shelves.

Common Applications of Dielines

Dielines are used across various industries and for numerous types of packaging:

- Retail Packaging: For products ranging from cosmetics to electronics, dielines help create boxes that are not only functional but also attractive to consumers.

- Food Packaging: In the food industry, dielines are essential for creating packaging that meets health regulations while being visually appealing.

- E-commerce: With the rise of online shopping, dielines are increasingly important for designing packaging that protects products during transit while being easy to open for consumers.

- Promotional Packaging: Special promotional items often require unique packaging solutions, where a well-crafted dieline can elevate the product’s presentation and appeal.

Conclusion

Understanding what a dieline is in packaging is essential for anyone involved in design or production. By serving as a blueprint that outlines how packaging will be cut, folded, and assembled, dielines play a critical role in ensuring accuracy, functionality, and visual appeal. By adhering to best practices and considering the nuances of different materials, designers can create effective dielines that contribute to successful packaging solutions. Whether for retail, food, e-commerce, or promotional products, a well-constructed dieline is key to delivering a polished and professional final product.