Choosing the right air valves and valve kits for your system can feel overwhelming, especially when pressure ratings come into play. But understanding how pressure ratings affect the performance and safety of your equipment is crucial. If you pick the wrong valve or kit, you could face leaks, malfunctions, or even dangerous failures. Let’s break down everything you need to know to select air valves and valve kits based on pressure ratings — in a simple, straightforward way.

Why Pressure Ratings Matter in Air Valves and Valve Kits

Pressure ratings essentially tell you how much pressure a valve or valve kit can safely handle. Imagine your air system as a balloon — if the pressure inside gets too high for the balloon to contain, it pops. Similarly, every component in an air system has a maximum pressure it can safely withstand.

When it comes to air valves and valve kits, the pressure rating ensures that the valve can control or release air without damage or leaks. If you underestimate your system’s pressure, you risk valve failure, which can lead to equipment damage or safety hazards. Overestimating pressure rating isn’t ideal either, since it often means paying more for parts that may be unnecessarily heavy-duty.

So, the key is matching the valve or kit pressure rating closely to your system’s operating pressure for optimal performance, durability, and safety.

Understanding Pressure Ratings: PSI, Bar, and More

Pressure ratings usually come in units like PSI (pounds per square inch) or Bar (a metric unit). It’s important to know which unit your system uses to avoid confusion.

-

PSI is common in the US and many industrial settings.

-

Bar is used in many parts of the world and scientific fields (1 Bar ≈ 14.5 PSI).

Check your equipment manuals or system specs to know the typical operating pressure. You’ll often see terms like “maximum operating pressure” (MOP) or “pressure range.” These give you a guideline on what valves and kits you need.

Different Types of Air Valves and Valve Kits by Pressure Rating

Not all air valves and valve kits are built the same. Here’s a quick rundown of common types categorized by pressure suitability:

-

Low-Pressure Valves: Usually rated up to 150 PSI, these are good for light-duty air systems, like small compressors or pneumatic tools. They’re often made of plastic or lightweight metals.

-

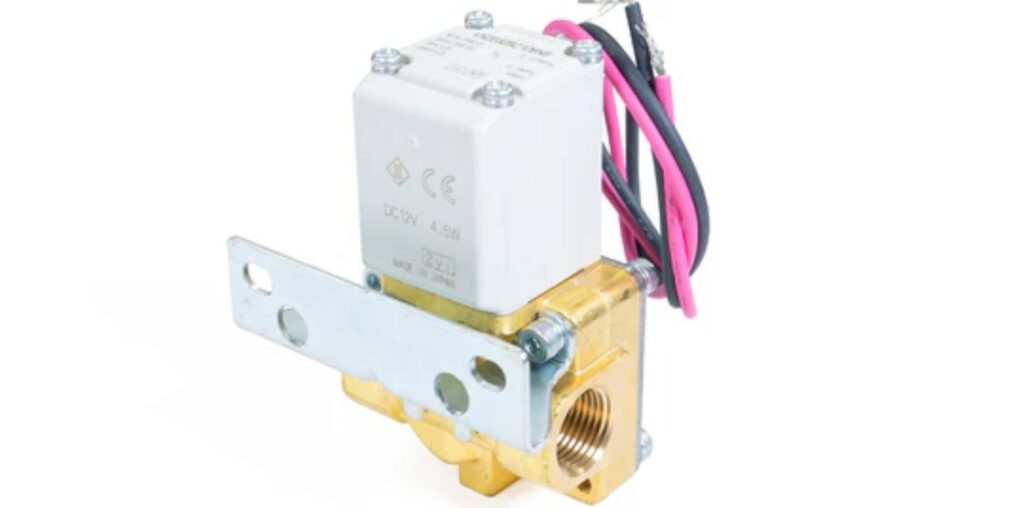

Medium-Pressure Valves: Rated between 150 to 500 PSI, these valves suit most industrial pneumatic applications and automotive air systems. Materials are stronger — usually brass or steel — to handle higher stress.

-

High-Pressure Valves: Rated over 500 PSI, these are specialized valves for heavy industrial machinery, hydraulic systems, or air tanks. They’re built with hardened steel or other high-strength alloys.

Knowing your system’s typical operating pressure helps you decide which category fits best.

How to Read Pressure Ratings on Air Valves and Valve Kits

When shopping for air valves and valve kits, pressure ratings are often stamped or printed right on the component or listed in the product specs. Here’s what to look for:

-

Maximum Pressure Rating: The highest pressure the valve or kit can handle safely.

-

Operating Pressure Range: The ideal pressure range for normal operation.

-

Burst Pressure: Some specs will include the burst pressure, which is the pressure that causes failure — usually much higher than max pressure and not recommended for use.

If the valve’s max pressure rating is below your system’s max pressure, don’t use it — it won’t last. But if it’s way above your system’s max pressure, you might be paying for overkill.

Matching Your Air System Pressure with the Right Valve

Step one: Identify your system’s operating pressure and max pressure. This info might be in the compressor’s manual, air tank label, or system documentation.

Step two: Choose air valves and valve kits with pressure ratings at or slightly above your system’s max operating pressure. For example, if your system maxes out at 200 PSI, aim for valves rated around 250 PSI. That little buffer ensures safety and reliability.

Step three: Consider the valve’s function. Some valves, like pressure relief valves, open to release excess pressure and protect your system. Their pressure rating determines the point at which they activate. Selecting the correct pressure rating here is crucial for safety.

Don’t Forget About Temperature and Material

Pressure isn’t the only factor affecting your air valves and valve kits. Temperature can influence the pressure rating and the material’s performance.

For example, a valve rated for 300 PSI at room temperature might handle less pressure if exposed to extreme heat or cold. Similarly, the material matters:

-

Brass valves handle corrosion well and perform in moderate temperatures.

-

Steel valves are stronger and often used for higher pressure or more demanding environments.

-

Plastic valves are usually limited to low pressure and low temperature.

If your system operates in harsh conditions, choose valves rated for those temperatures and environmental stresses.

Valve Kits: What You Should Know About Pressure Ratings

Valve kits often include several components — the valve itself, seals, springs, and other parts. Each piece should be compatible with your system’s pressure rating.

Don’t assume the entire kit is rated for the same pressure just because one part is. Check the specifications for the kit as a whole. If parts aren’t rated for your system’s pressure, the whole kit could fail.

Also, when replacing or upgrading valve kits, always pick kits recommended for your pressure range. Cheap or mismatched kits might seem like a good deal but can cost you more in repairs later.

Safety Tips When Selecting and Installing Air Valves and Valve Kits

-

Always confirm the pressure rating before purchase. Don’t guess or assume.

-

Consult the manufacturer’s guidelines to ensure compatibility with your system.

-

Install valves and kits correctly — improper installation can cause pressure leaks or failures regardless of rating.

-

Regularly inspect your valves and kits for signs of wear or damage, especially if working near max pressure.

-

Consider professional help if you’re unsure about pressure ratings or installation.

Common Mistakes to Avoid When Choosing Based on Pressure Ratings

-

Choosing valves rated below system pressure: This is the most common and dangerous mistake.

-

Ignoring temperature effects: Pressure ratings can shift with temperature changes.

-

Over-specifying without reason: Buying super high-pressure valves for low-pressure systems wastes money.

-

Neglecting the entire valve kit rating: Don’t just focus on the valve itself.

-

Not considering valve function: Different valves need different pressure ratings depending on what they do.

Final Thoughts: The Right Pressure Rating Makes All the Difference

Picking the right air valves valve kits based on pressure ratings isn’t just about numbers. It’s about matching your system’s needs with components that ensure smooth, safe, and reliable operation. Understanding your system’s pressure, checking specs carefully, and choosing materials and kits suited to your environment will save you headaches and costly repairs down the line.